|

|

| Contact us |

JAcube (Beijing) Technologies Co., Ltd.

Add:1-1-1G, Changning Building, Kandan bridge,fengtai district,Beijing,China

Postcode:100070

Tel:010-83678322

Moblie:13905514792

Email:sf312@hotmail.com

Homepage:www.jacube.com

|

|

|

|

|

| JA Re-circulation Huelium Liquefy |

| Product Overview |

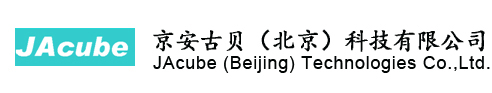

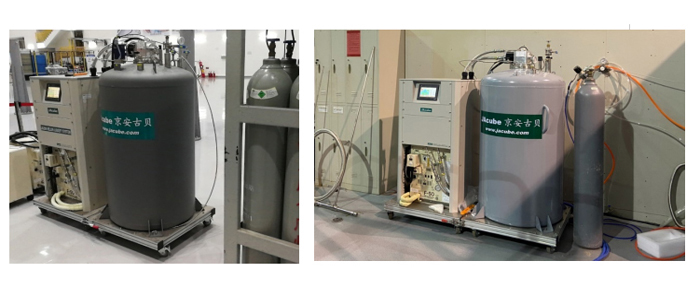

JA series helium recovery liquefaction system is personalized and professionally designed according to the user's site, with stainless steel recovery pipelines equipped with professional recovery joints laid on the user's site to quickly complete helium recovery. Then, it is pressurized and stored in standard helium gas cylinders by a high-speed helium compressor, and operates fully automatically with a recovery efficiency of over 94%

CP/CPC helium purification system uses liquid nitrogen and G-M refrigeration units as cold sources, and performs gas-liquid separation and low-temperature adsorption purification of residual impurities in the recovered helium gas components in the temperature range of 70K-20K to obtain high-purity helium gas with a purity of>99.999%. It operates fully automatically with a purification flow rate of 1-200m3/h

JA helium liquefaction system uses a G-M refrigeration unit as the cold source, with an integrated wet structure design and an efficient heat exchange assembly with independent intellectual property rights. It completes helium liquefaction and then achieves liquid helium distribution and direct injection through liquid helium transmission pipelines. It operates fully automatically with a liquefaction rate of 5-200L/D (1-3 psi).

|

Advantages Explanation

JAcube Helium pressurized unit consists of stainless steel recycling, non-enclosed recycling interfaces, prepare press systems, large volume impermeable gas bag, helium compressors, high pressure helium gas filling systems, gas cylinder packs, decompress system; automatically running, reduce operator work intensity.

Helium purification unit |

¡ù Over 18 years of experience in designing, integrating, testing, and operating helium recovery, purification, and liquefaction systems;

¡ù Using G-M refrigeration unit as the cold source, with stable performance;

¡ù Overall recycling rate>94%;

¡ù Provide a one-stop after-sales service system for all JA system unit equipment (recycling/purification/liquefaction/chiller units);

¡ù JA system software is upgraded for free for life, and the equipment is maintained for life;

¡ù The research and development sites in Beijing and Hefei provide users with year-round fast after-sales service;

¡ù Provide professional upgrade and expansion services for users;

|

JARL operating mode |

| Closed loop self circulating liquefaction mode |

| The helium evaporated from the low-temperature instrument equipment's liquid helium dewar is directly transported through a metal pipeline into the JASC helium liquefier for liquefaction. The liquid helium then enters the low-temperature instrument equipment's dewar through an infusion tube, forming a closed-loop self circulating liquefaction mode; |

¡ù Small footprint, does not occupy laboratory space;

¡ù Omitting the recycling and purification units reduces equipment investment and maintenance workload;

¡ù Helium or liquid helium can be replenished through high-purity helium gas cylinders;

|

|

| Direct liquefaction mode |

| The helium gas evaporated from the low-temperature instrument equipment's liquid helium dewar enters the external JA helium liquefier through a metal pipeline for liquefaction. The liquefied liquid helium is stored in the JA helium liquefier's liquid helium dewar, and then continuously or periodically replenished to the low-temperature instrument equipment through an infusion tube. |

¡ù Omitting the recycling and purification units reduces equipment investment and maintenance workload;

¡ù Avoid liquid helium/helium gas loss caused by the reheating of low-temperature instruments and equipment;

¡ù Flexible to use and can be upgraded to a full process helium recovery, purification, and liquefaction system at any time;

|

|

| Full process helium recovery, purification, and liquefaction system |

| JARL system consists of a recovery unit, a purification unit, and a liquefaction unit, which completes the recovery, pressurization, purification, and liquefaction processes of low-temperature instrument equipment for hair care helium gas; Each unit can operate independently and fully automatically; |

¡ù A complete helium recovery, purification, and liquefaction system;

¡ù It can achieve 100% recovery of excess cold helium gas from volatile helium gas and liquid helium injection;

¡ù Each unit can operate independently and automatically, recovering helium gas for pressurized storage/high-purity helium gas preparation storage/liquid helium preparation storage;

¡ù It can serve as a helium recovery, purification, and liquefaction platform to achieve resource sharing;

|

|

|

|